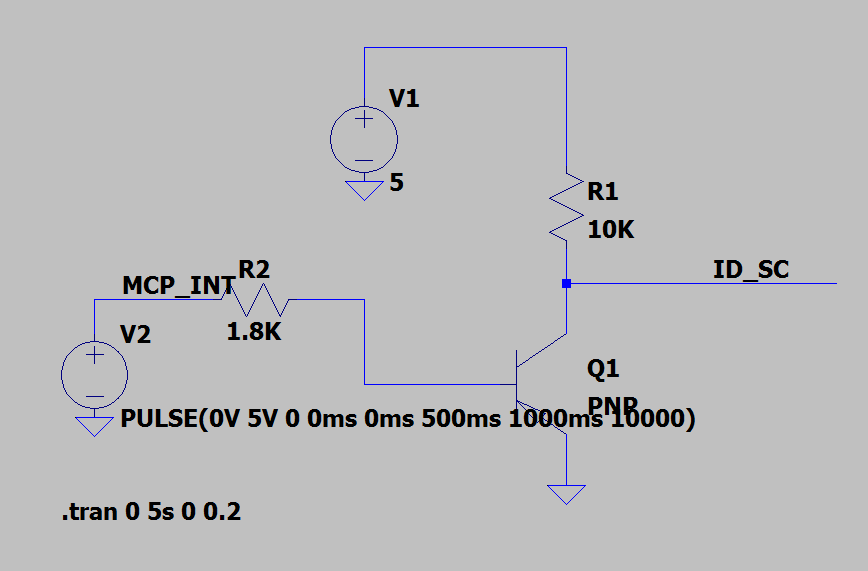

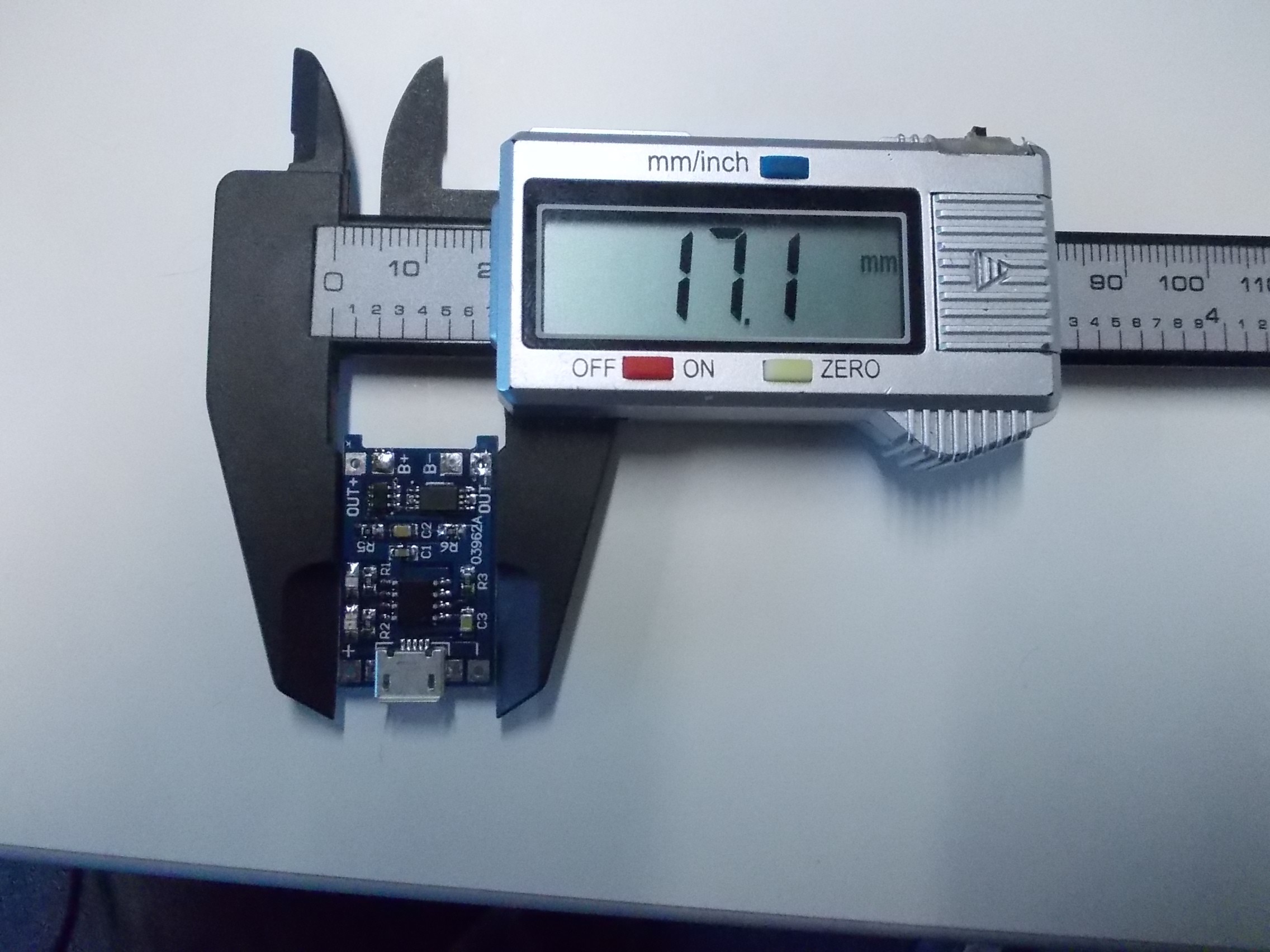

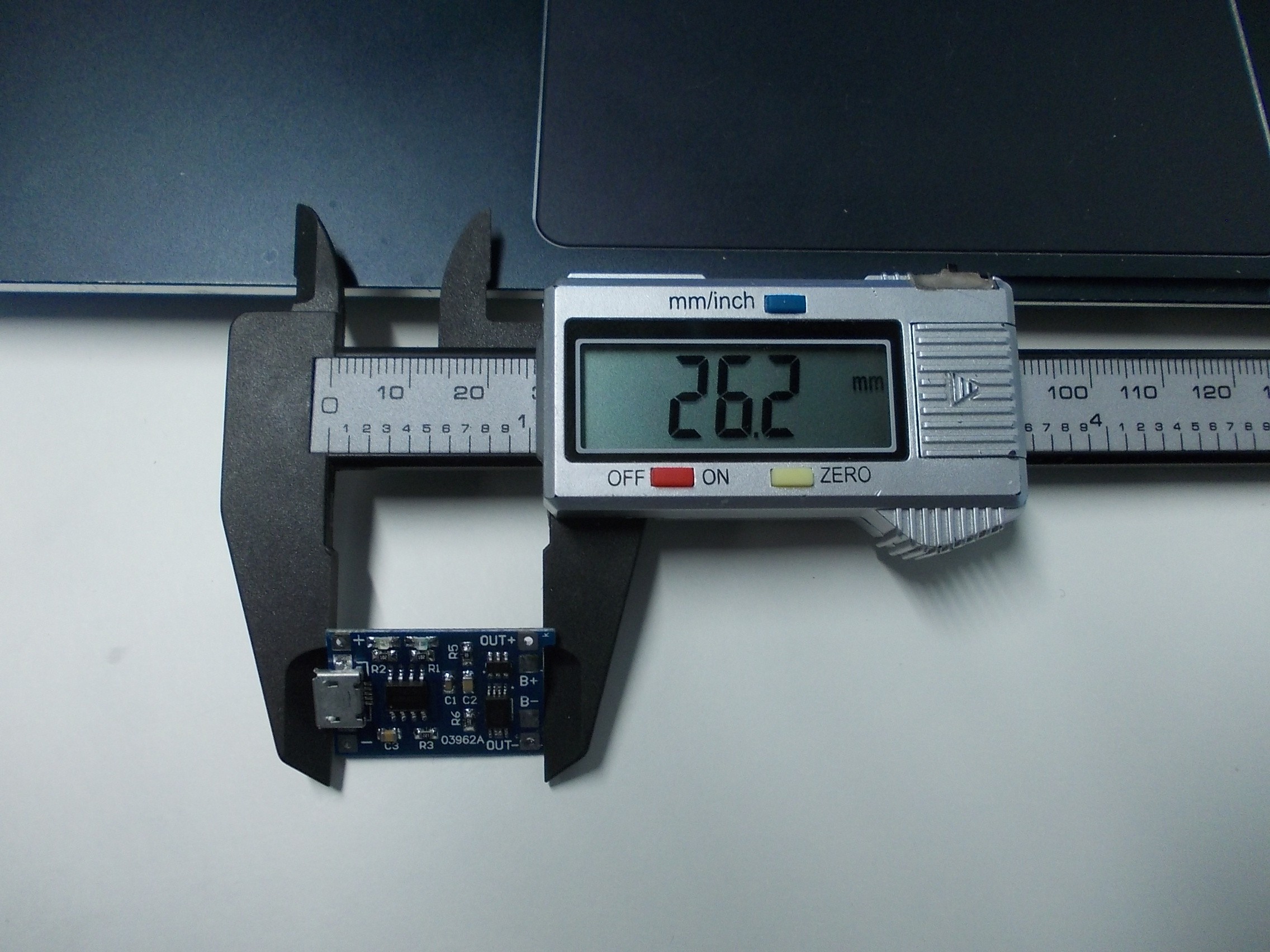

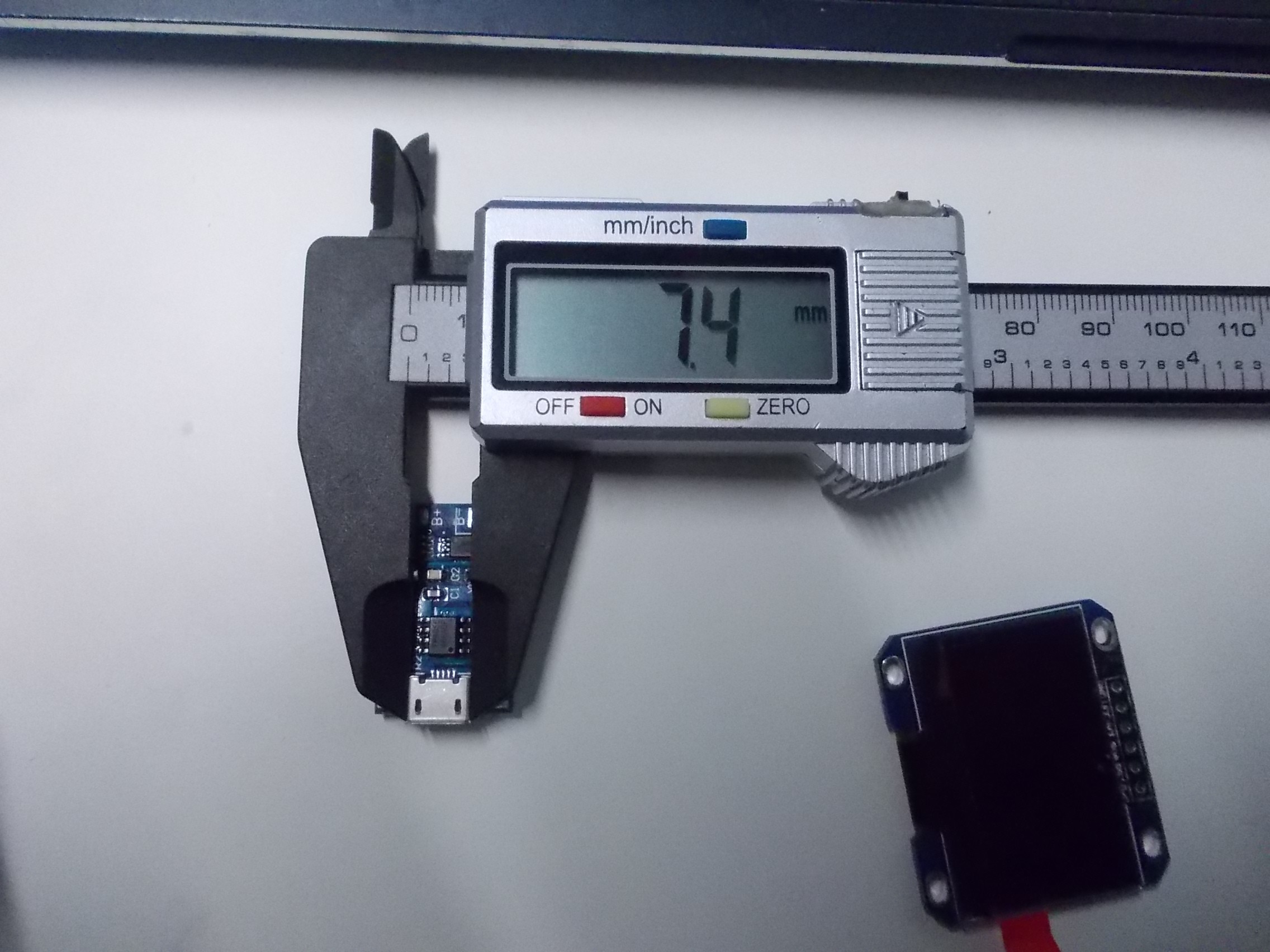

There are several undesirable hardware situations that need to be detected, that can't yet be detected by ZeroPhone. For example, the charging circuit can pull up to 1.5A from the charger. If the charger is not capable of providing that current, it will, possibly, drop the voltage and start overheating. It could also possibly mess with the LiIon charging board - while the chip used claims to work down to 4.0V (which in itself is weird, like, can you even charge a battery from this?), there's no guarantee the overloaded charger won't do some weird things. There are no free ADCs that could be used for determining whether the voltage is out of the bounds (there's one free ADC, but it's reserved for user applications), so technically a comparator could be used, using some free GPIOs on the MCP23017.

The 5V DC-DC chip used on the Chinese step-up breakout, while probably has some overload protection, has no way of notifying the user about output overload, while it could be very helpful while working with some USB devices. Again, a comparator could solve this.

The battery is connected to the ATMega ADC and, with firmware allowing that, could be read by the Pi Zero through ADC. However, there's no hardware shutdown when the battery is lower than 3.0V - there's a protection circuit that shuts off at 2.5V, but I personally would like the cutoff voltage to be at least 3.0V. There's already a FET that cuts off VBAT in the current version of boards (Gamma), but it's only controlled from MCP23017, which, again, is controlled by software.

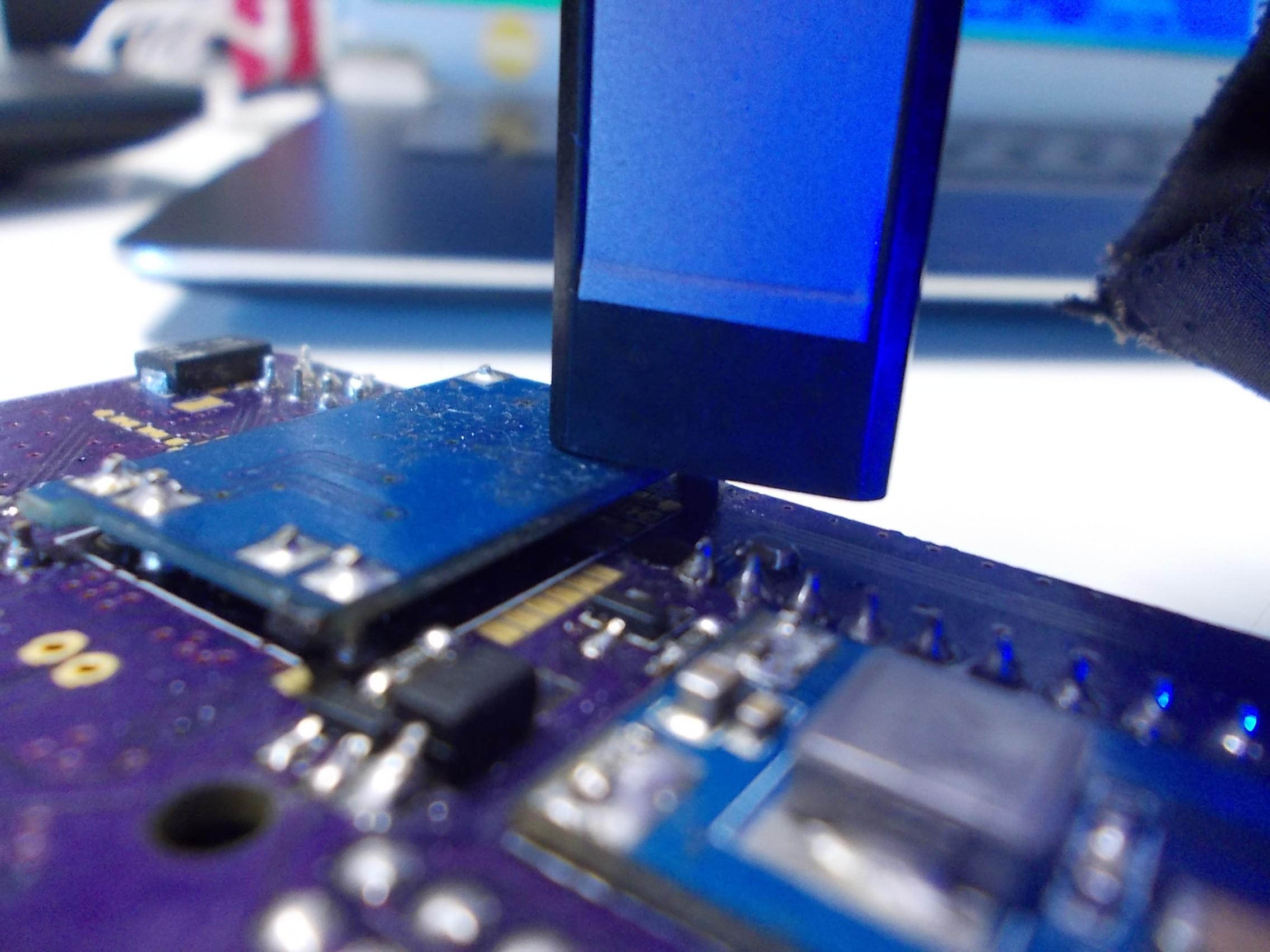

Also, some of the charger circuits are prone to going into some kind of thermal runaway when overheated (static discharge might play a role, too - at least I have no other explanation yet). They don't have to be put on the charger for this to happen - and if it happens, it's a bad thing, at best, the battery will discharge quickly. It's definitely a fault of the charger boards, but we still need to be able to detect it.

A solution I imagine would be using a quad comparator out of the popular ones, and having some kind of reference for it (that'd also be sourceable, solderable and cheap, just like the comparator has to be).