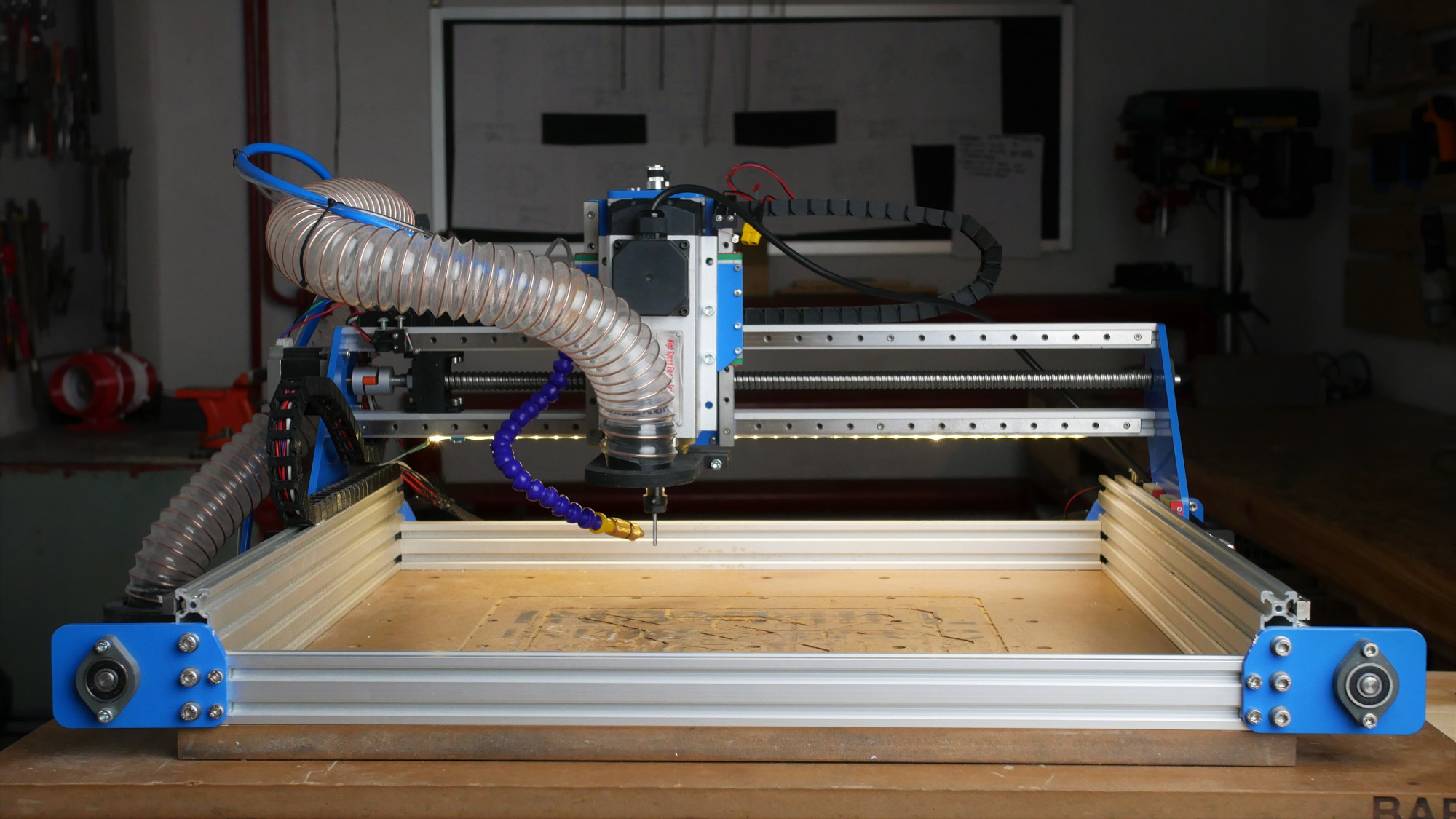

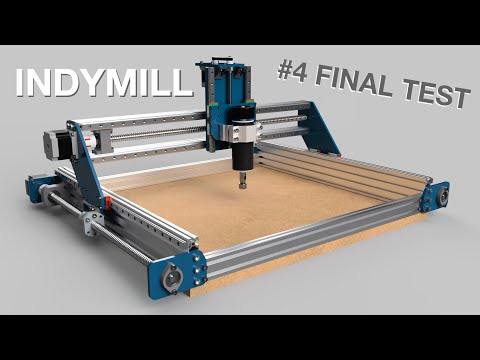

IndyMill is an open source DIY CNC machine that is mostly made out of metal. It was designed with simplicity and minimalism in mind! This project is not aiming to be the most heavy duty CNC machine out there, it is meant to be easy and inexpensive to build so that anyone can get a hand on precise CNC machining in many materials including metal. Designed by Nikodem Bartnik.

Here are just some of the features of this machine:

- Aluminium profiles (2080 and 2040)

- Compatible with Nema17 and Nema23 on X and Y axis (without redesigning a plate Z axis is only compatible with Nema23)

- Made with ball screws, linear rails and 6mm steel plates to ensure rigidity

- Can be easily scaled up, you just need to use longer profiles, ballscrews and linear rails

You can find more info at Indystry.cc

This machine is open source, so above you can find all of the files that you need to build it. You can also check out videos below to see the build process. As for now, the machine was tested with various kinds of wood, MDF, acrylic and aluminium. It is able to machine all of those materials even with a small 500W spindle. You can also find more information on my website: Indystry.cc

You can find parts list in PDF or XLSX above but you can also find it here:

- At indystry.cc/indymill you can find a full table with all needed parts

- Google Drive Parts List here you can find an online parts list

- You can buy some of the parts on my store

This project is open source so you can find all the files that you need to build it above for free. You can easily build it just by taking a look at some images on my website and my videos. But if you would like to get a PDF instruction that simplifies the build process, you can easily print it put or it on a smartphone or computer. You can get one through link below and at the same time support my projects! You don't need it but it may help a little :)

- Design a better, bigger cable chain