- Adds load cell as the brake pressure sensor.

- replaces lower part of the spring housing with a 3D-printed one.

- Adds Adafruit ItsyBitsy M4 express to process load cell data and potentiomenter readings as an independent (from the wheel) HID joystick with 16-bit values. Un-invert the values reported by pedals while we're at that.

Humans easily adapt to control car braking by applying pressure. Logitech pedals use potentiomenters that read pedal displacement. Relationship between the applied pressure and the displacemmment is controlled by the brake's spring with a rubber block intended to make the relationship non-linear. Unfortunately, it squeezes whe wide range of high pressure values at the end of the pedal travel into a rather narrow range of the pedal movement which Logitech software then attempts to normalize into something more sensible.

It mostly works, but in practice I've found it rather hard to modulate the brake pressure precisely. One moment the car does not brake enough, then all of a sudden ABS goes nuts (or the car spins out). It just does not behave like a real car brake.

So, after eyeballing various higher-end pedals I've decided that I'm not that interested in spending my toy budget on the ready-made gear. Instead, I've figured that I can just mod the pedals using mostly off-the shelf components and whatever I had at hand.

TL; DR; It worked surprisingly well. Eventually.

-

Logitech G29/G920 pedals. The mod may work with G27 or other similar Logitech models, but you may need to tweak the spring housing model to fit.

-

$15 Adafruit ItsyBitsy M4 Express

It's amazing how much stuff you can cram into $15 worth of hardware:

-

ATSAMD51 32-bit Cortex M4 core running at 120 MHz

You get a real 32-bit ARM processor, with tons of peripherals and you can program it in Python, if you want to. Why anyone is still using AVR-based overpriced and underpowered Arduino boards these days is beyond me.

-

Floating point support with Cortex M4 DSP instructions. -- M4 can do a lot of signal processing, if needed.

-

512 KB flash, 192 KB RAM -- should be enough for everyone, right?

-

2 MB SPI FLASH chip for storing files and CircuitPython code storage.

Another option is Feather M4 ($23) which uses the same processor as the

ItsyBitsy M4and comes with some breadboard space which would be handy.You could also save few bucks and go for QT Py ($6), Trinket M0 ($9), or ItsyBitsy M0 ($12). These boards use

Cortex-M0and are slower than theCortex-M4on theItsyBitsy M4, but should still be more than sufficient to do the job.Other thoughts:

About any chip with an USB interface, couple of GPIO pins for I2C and three ADC-capable inputs could do the job.

ItsyBitsy M4is way overpowered for that and was largely chosen for convenience of writing software in Python.Surprisingly, not that many low-cost Cortex-M based boards have USB support. My usual go-to

DiscoveryandNucleoboards fromSTMuse USB for built-in STLink debugger and only pass through UART to the host.Trivia bit: $13 STM's Nucleo-32 which is based on

stm32f431kbusesstm32f723for the built-in ST-Link debugger.F732alone costs as much as the board and is much more capable than thestm32f4chip it debugs. How can one buy the whole board for less than the sum of the parts is a mystery to me. Can't complain though.ESP32 may be an interesting option for interfacing with the computer via Bluetooth, but that was considered to go beyond the

keep it simpleapproach I was going for. -

-

$30 FX29K0 100lbf/50kg load cell with I2C interface.

- Part number: FX29K0-100A-0100-L

- Datasheet for FX29 load cells.

- Datasheet for

zsc31014which is the measurement controller inside the FX29 load cell.

There are quite a few variants of the load cell. You need the one starting with

FX29KorFX29J, and ending with0100-Lpr0500-N. If you useFX29K/FX29Jfollowed by a digit other than0, you will need to adjust the I2C address in thecode.py.The cell costs about $30 and is available from the usual sources.

-

Female DB-9 connector.

Used to read the stock potentiomenter values via the reguler DB-9 connector from the pedals that normally plugs into the wheel base.

I've repurposed an old serial cable I had in my

junk that may be useful one daybin.

-

That turned out to be the easiest way to get things working. I've considered multiple alternatives, but this method ended up winning based on the

results delivered/annoyance causedratio.-

My repo with the modified CirquitPython

The only changes are to ass

PEDALSUSB HID device forItsyBitsy M4 Expressboard. If you want to use a different board, you'll need to make similar changes for that board. -

Pedals software (this repo)

It's a simple python script that reads the values from

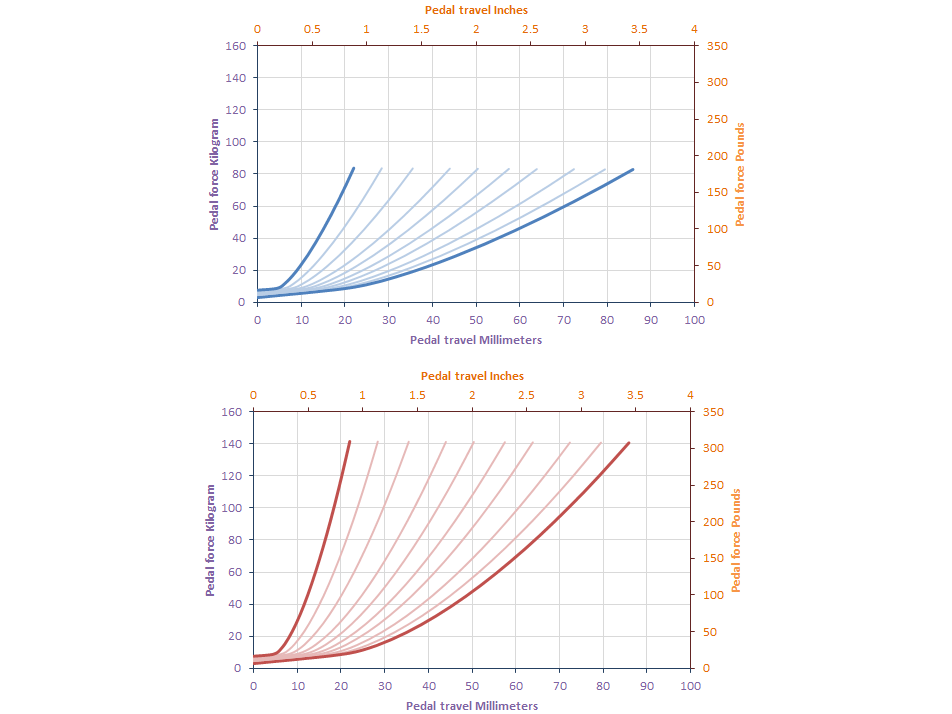

FX29and the values of the stock potentiometers and reports them via USB. It also continually prints all the values over the serial port. It could be used to measure the relatinship between pedal displacement and the reported load. E.g. here is what my brake pedal reports depending on the spring setup:

The result is roughly comparable to the much more expensive Heusinkveld Sim Pedals Ultimate:

-

- Coins. I've used Euro 10c, Danish 2 kroner (yay for a center hole!) and an US 25c coins. You could probably use other coins, possibly filed down to size, or find appropriately sized washers.

- M4-0.7x20 screw + nut, but the size is not particularly critical, we just need a bump that will push on the load cell.

First mod version was prototyped using a bunch of schedule 40 PVC pipes and couplers. It didn't quite work out. I had to build both upper and lower parts of the spring housing. Making the parts telescoping into each other was hard to do within the limited size choices and the constraints imposed by the pedal frame. Without parts snugly fitting into each other, the spring buckles under the load and the whole contraption flies apart. It turns out g29 pedal design uses a number of subtle tricks to constrain spring housing motion to prevent spring buckling.

See Build.md for the gory details.